|

|

|

|

![]()

Example:

Clamp = For clamping. Not resizing Nitro engine sleeves. Image source: Major industrial catalog with selling price of $1.78. Why pay 20-40 dollars for this? It is not a resizing fixture it's a CLAMP!

The CLAMP will not provide accuracy, or safely compress sleeve cylinder

in a round uniform state. An experienced craftsman / person experienced

with close tolerance inspection tools, such as micrometers that read

in 0.0001" (one-tenth of one-thousandth inch) increments, would

see the poor quality resizing results/out of round measurements received

this method. Simple measurements, using simple inspection tools, is

not sufficient ......You must hold exact close tolerances when resizing

a nitro engine sleeve cylinder. Most RC hobbyists do own digital calipers/Micrometers

that read in 0.0005" (one half of one-thousandth) at best....More

common are the mics / calipers reading 0.001" (one-thousandth of

one inch) increments. Either way, not even remotely acceptable accuracy

is there to be found by using above type hardware as a tool. Or trusting

tests/inspections made with inappropriate inspection equipment.

Unfortunately, racers sending us damaged sleeves for rework that do not run well know better now.

Remember. In order for your engine to run properly the sleeve bore and piston diameter MUST be concentric and even / uniform within 0.0001"(one tenth of one-thousandth of an inch). A sleeve that is resized out of round a half thousandth will not re-lap at re-break-in resulting in a poor seal. This causes blow-by providing an inferior power stroke reduced overall horsepower.

Please be advised that the number of Piston and Sleeve sets we have received for reworking has gotten very large. The inspections immediately reveal in every set, most prevalent in this order:

- Out of round Cylinder ID and OD a half thousandth minimum.

- All tightness at top with no taper.

- Scratched piston surfaces.

- Sleeve cylinder liner chrome plating scratches.

- Piston failure. (Chips and cracks resulting unsalvageable conditions)

- Sleeve liner deep gouges and excessive chipping at porting windows, resulting unsalvageable conditions.

*RayAracing offers a rework service for the P&S sets resized using any inferior/unsuccessful method! HOWEVER, WE CANNOT HELP YOU SHOULD YOU ENCOUNTER PISTON FAILURE/SLEEVE PLATING DAMAGE!!! *

In Closing:

The over all impression we hope you get here is that there are many

less expensive methods of pinching a sleeve and making it smaller. RayAracing

tooling is profiled to give ability to very mildly reform the sleeve

cylinder and maintaining an exact round state with no flats, kinks,

oval like results, or damaged plating conditions. All you have to do

is inspect the piston and sleeve surface finishes of one of our resizings

(after a gallon or so running) and compare it to one that was resized

with a cheap resizing tool/other inferior process. You will note a uniform

and nicely lapped in seal surface on our work. The other will be uneven

and guaranteed to have scratches or other unwarranted surface finish

conditions sacrificing reliability, performance, and longevity.

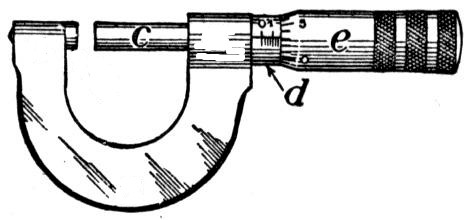

Please note the micrometers you will see RayA making use of in the video presentations.

Vernier Micrometer:

The micrometer is commonly used in industry for securing small measurements. Its purpose is to measure objects with extreme accuracy.

c is the spindle

d is the sleeve

e is the thimble

Vernier micrometers can measure to ten-thousandths of an inch (0.0001").